Seawalls, Sheet Pile and Revetments

-

Seawalls and Bulkhead Systems

Seawalls, bulkheads and revetments serve as barriers intended to dissipate wave energy, and prevent erosion, scour and damage to structures.

There are a number of types of retaining walls: gravity, cantilever and pile-supported. Many include an outer wall of steel or composite sheet pile that is meant to maintain stability. Seawalls are most commonly made from concrete. Revetments are slopes usually made out of riprap or wire baskets filled with rocks (gabions.)

Inspection Frequency

The American Society of Civil Engineers (ASCE) recommends that concrete, composite and protected steel structures be inspected every 5 years in saltwater, brackish water and high current areas (above 0.75 knots). In fresh water or areas with less than 0.75 knot current, these structures should be inspected at least every 6 years.

These intervals are only for newer structures that are in Good or Satisfactory condition. Older facilities should be inspected anywhere from every six months to 4 years, depending on level of deterioration. A baseline inspection should be performed to determine the condition rating of the wall. The initial inspection, type of facility and anticipated deterioration can then be used to recommend inspection frequency.

-

Cleaning

Proper maintenance is critical to ensure that seawalls and bulkheads remain sound. Cleaning is the first step to a regular maintenance program.

A significant amount of stress is placed on a seawall/bulkhead. Weep holes are designed to relieve the hydrostatic pressure placed on the wall. These relief openings can become clogged with debris, keeping them from flowing freely.

Marine growth doesn’t just clog weepholes, it adds weight, hides damage and can compromise the function of the seawall.

Marine growth should be removed annually.

A clean seawall/bulkhead:

• Clears the way for a visual inspection

• Is more aesthetically pleasing

• Allows weep holes to drain

• Removes plant growth creating a wedge in cracks and crevices

• Reduces safety hazards associated with heavy marine growth

• Avoids costly replacement by allowing for regular maintenance to be performedCatching damage early is key to preservation and avoiding a costly replacement.

-

Inspections

Our full inspection report includes before and after photos of the cleaning, findings from the inspection and recommendations for repairs.

Some of what we look for above and below the surface:

• Corrosion and pitting—Corrosion is a major cause of weakness or failure of sheet pile. The thickness of all steel components should be measured using ultrasonic testing (UT) to determine loss from corrosion. The areas that see the highest rate of corrosion are typically at the mudline, the high tide line and in the “splash zone” just above the high-water mark.

• Settlement—Sinkholes that develop behind the bulkhead are a direct result of loss of fill. Settlement can be caused by fill loss through holes resulting from corrosion or from separation in the sheet pile sections.

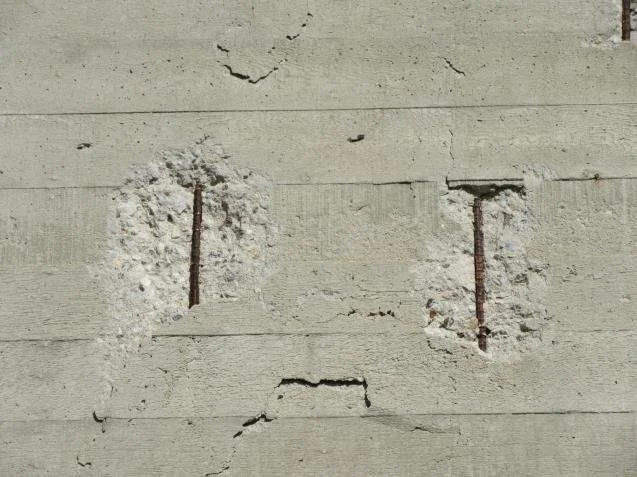

• Cracking, spalling, scaling and honeycombing—The breakdown of the finished concrete surface begins with scaling. This gradual loss of surface can cause voids (honecombs) to form. Depending on the type of cracking or spalling, structural integrity of the wall can be compromised. Hydraulic cracking can lead to the corrosion of structural supports.

• Scour—The toe of a seawall or bulkhead is susceptible to loss of material and undermining as a result of wave or tidal movement.

• Misalignment, separation and bulges—gaps in concrete or separation or bulging of the interlocking sheet pile can be indications of potential failure of part or all of the wall system.